automotive

Sector

Engineered for precision and endurance, our automotive-grade steel wire meets the rigorous demands of modern vehicle manufacturing. From control cables and seating frames to engine components and electrical systems, our wire is designed to perform under high stress and in extreme environments.

-

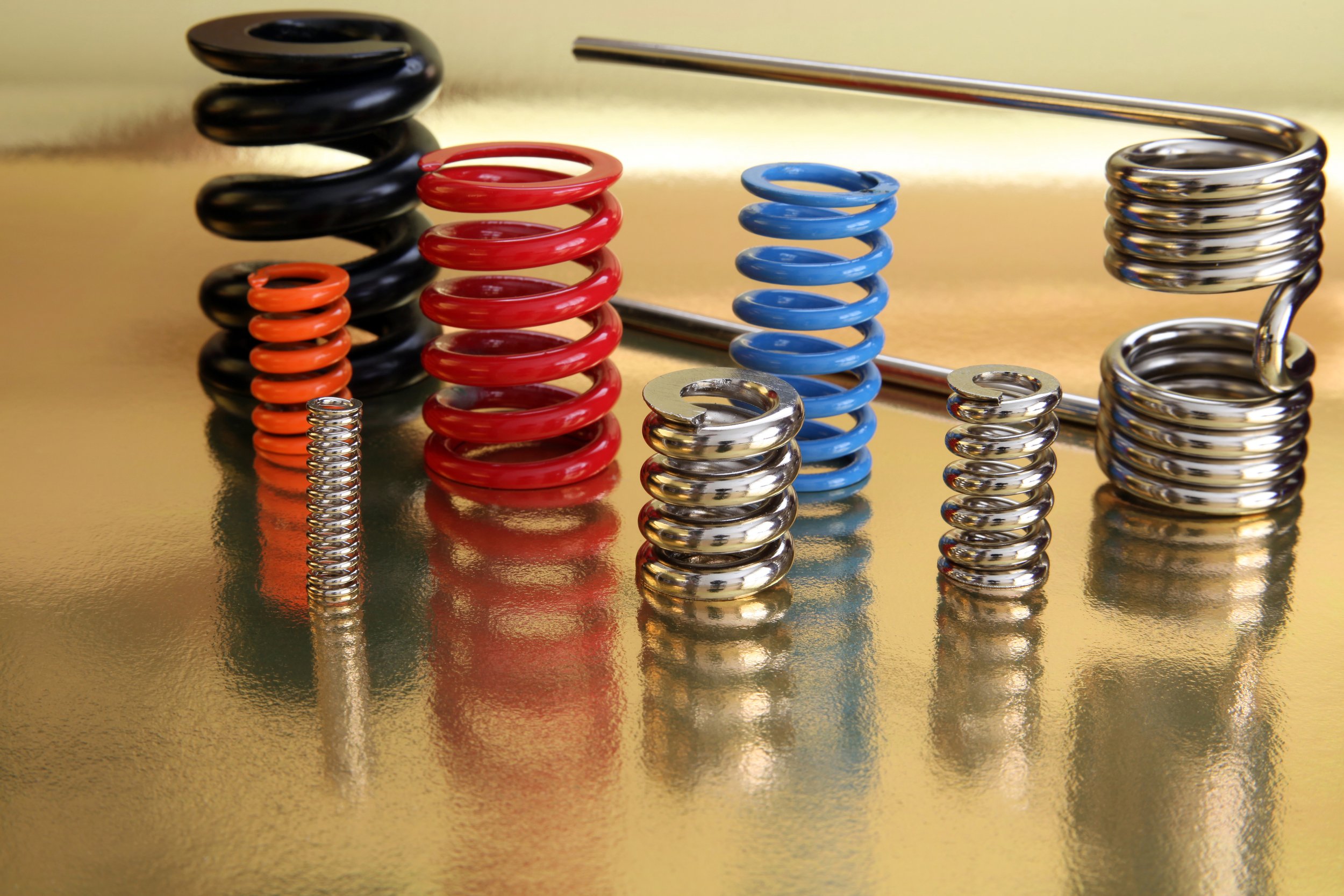

Our high carbon steel wire is engineered with consistent mechanical properties, ensuring uniform dimensions throughout the spring forming process. Ideal for demanding automotive and industrial applications, BEKA wire is tested with precise quality control to meet stringent industry standards.

-

BEKA’s steel wire is engineered with consistent mechanical properties, ensuring uniform dimensions essential for smooth and reliable control cable performance. Every batch is tested with precise quality measurements to meet or exceed industry standards.

-

Engineered for strength and durability, BEKA’s steel wire is manufactured to meet automotive-grade specifications, ensuring reliable performance in wiper arms, springs, and blades. Our material is developed to align with engineering standards required by leading OEMs.

-

C Rings play a critical role in automotive seat assembly, where safety and reliability are non-negotiable. BEKA supplies high-standard coated steel wire specifically designed for C Ring manufacturing, ensuring seamless performance in automated tool systems.

-

Our high carbon steel wire is developed with consistent mechanical properties, ensuring the structural strength of seat components during both forming and long-term use. Designed for demanding automotive applications, it delivers the durability and reliability needed for safety-critical parts.